Case hardening is used in many industries to improve the wear characteristics and extend the lifetime of steel parts, such as cutting tools and bearing surfaces. Laser heat treatment is one of several selective hardening techniques, the CO2 laser performing this task in niche applications for over 30 years. However, in the past few years the high power direct diode laser has emerged as a viable alternative source with broader applicability.

Case Hardening

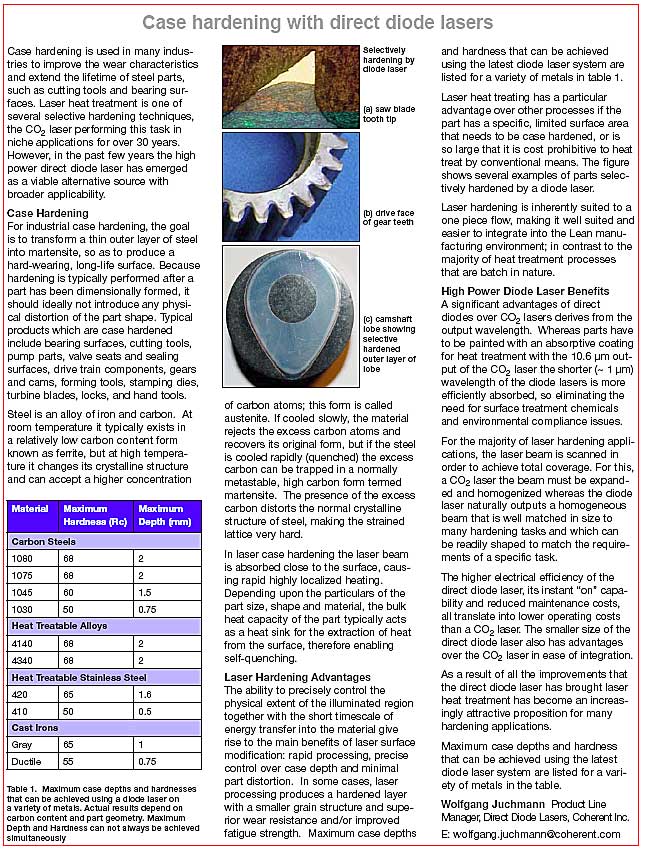

For industrial case hardening, the goal is to transform a thin outer layer of steel into martensite, so as to produce a hard-wearing, long-life surface. Because hardening is typically performed after a part has been dimensionally formed, it should ideally not introduce any physical distortion of the part shape. Typical products which are case hardened include bearing surfaces, cutting tools, pump parts, valve seats and sealing surfaces, drive train components, gears and cams, forming tools, stamping dies, turbine blades, locks, and hand tools.

Steel is an alloy of iron and carbon.........

View Document (140Kb)

Copyright of ©2010 AILU

We make every effort to trace copyright. If inadvertently we have not attributed copyright or attributed it incorrectly, please contact us using our webform or by emailing dlm@ailu.org.uk and we will rectify the situation.

Disclaimer

To view disclaimer details click here