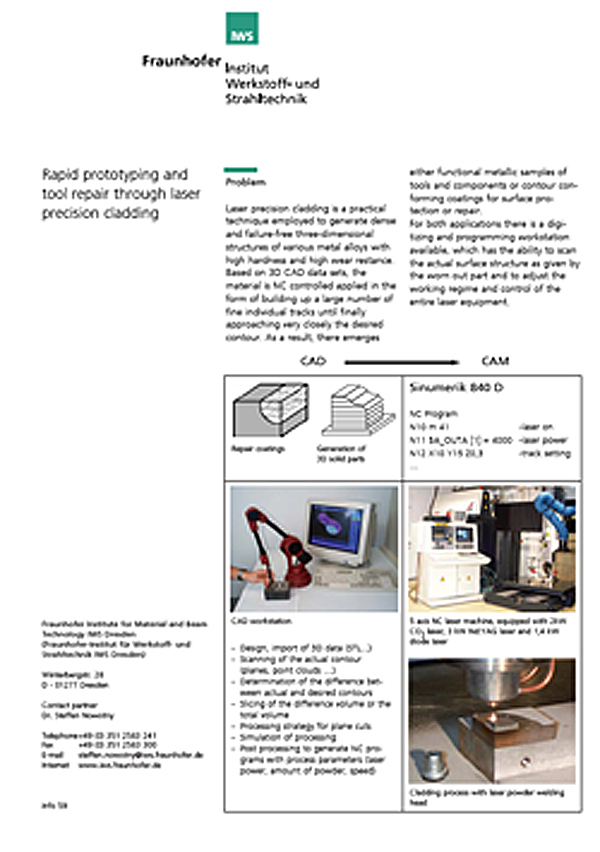

Laser precision cladding is a practical technique employed to generate dense and failure-free three-dimensional structures of various metal alloys with high hardness and high wear resistance. Based on 3D CAD data sets the material is applied under NC control in the form of a large number of fine individual tracks until finally closely approaching the desired contour. As a result either functional metallic samples of tools can be produced or else components or contour conforming coatings can be applied for surface protection or repair. A digitizing and programming workstation can scan the actual surface structure of the worn out part and adjust the working regime and control of the entire laser equipment. Technical Parameters: Laser - affordable CO2 or Nd:YAG laser with 1 kW power are generally sufficient; Welding additions - Commercially available steel Co Ni base powders as well as hard material powders (WC Cr3C2 VC); Accuracy: - Minimum wall thickness about 0 5 mm form deviation max ± 0 1 mm surface roughness (material and geometry dependent) Rz = 20 - 200 m; Productivity - Build-up rate (material and geometry dependent) 15 - 75 cm3 h-1 with a 1 kW CO2 laser

View Document (270Kb)

Copyright of ©2006 Fraunhofer Institute IWS Dresden

We make every effort to trace copyright. If inadvertently we have not attributed copyright or attributed it incorrectly, please contact us using our webform or by emailing dlm@ailu.org.uk and we will rectify the situation.

Disclaimer

To view disclaimer details click here