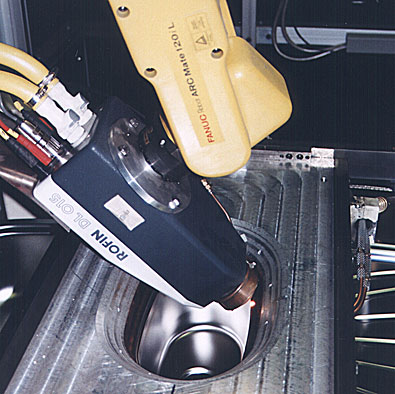

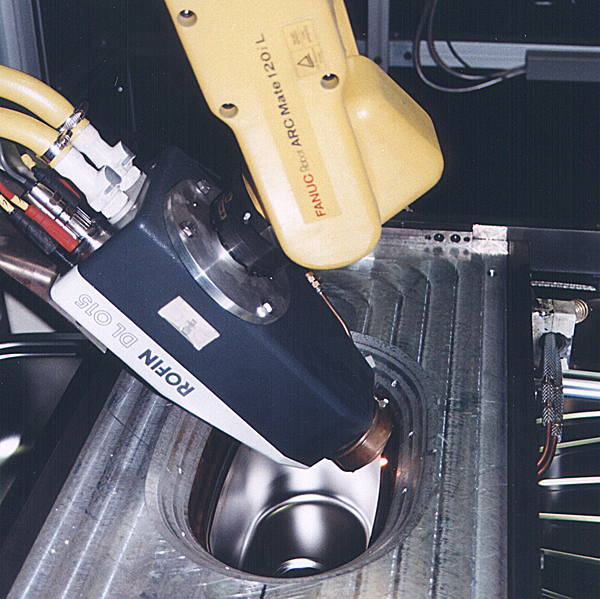

This photo shows a Kitchen sink being welded with a laser. The process involves a stainless steel part being welded with direct diode laser power kW. Industrial sector:This is applicable to the consumer durable and general industrial sectors. Other notes: many home and industrial kitchen wares benefit from this special type of laser welding particularly cooker hoods sinks and professional supermarket refrigerators or chip shop fryers. The diode laser welds in a conduction-limited way as opposed to more familiar ‘keyhole’ deep penetration welding. The advantage is that this sheet steels can be overlap welded with a broad smooth seam. The edges of the seam show no step where the bond merges from one layer to two; negligible subsequent finishing is required. Such a process also has the advantage of being far more tolerant to gaps and using a laser with an order of magnitude lower running costs than some alternatives.

View Picture (308kB)

Copyright of Rofin-Baasel UK Ltd

We make every effort to trace copyright. If inadvertently we have not attributed copyright or attributed it incorrectly, please contact us using our webform or by emailing dlm@ailu.org.uk and we will rectify the situation.

Disclaimer

To view disclaimer details click here